ETCH

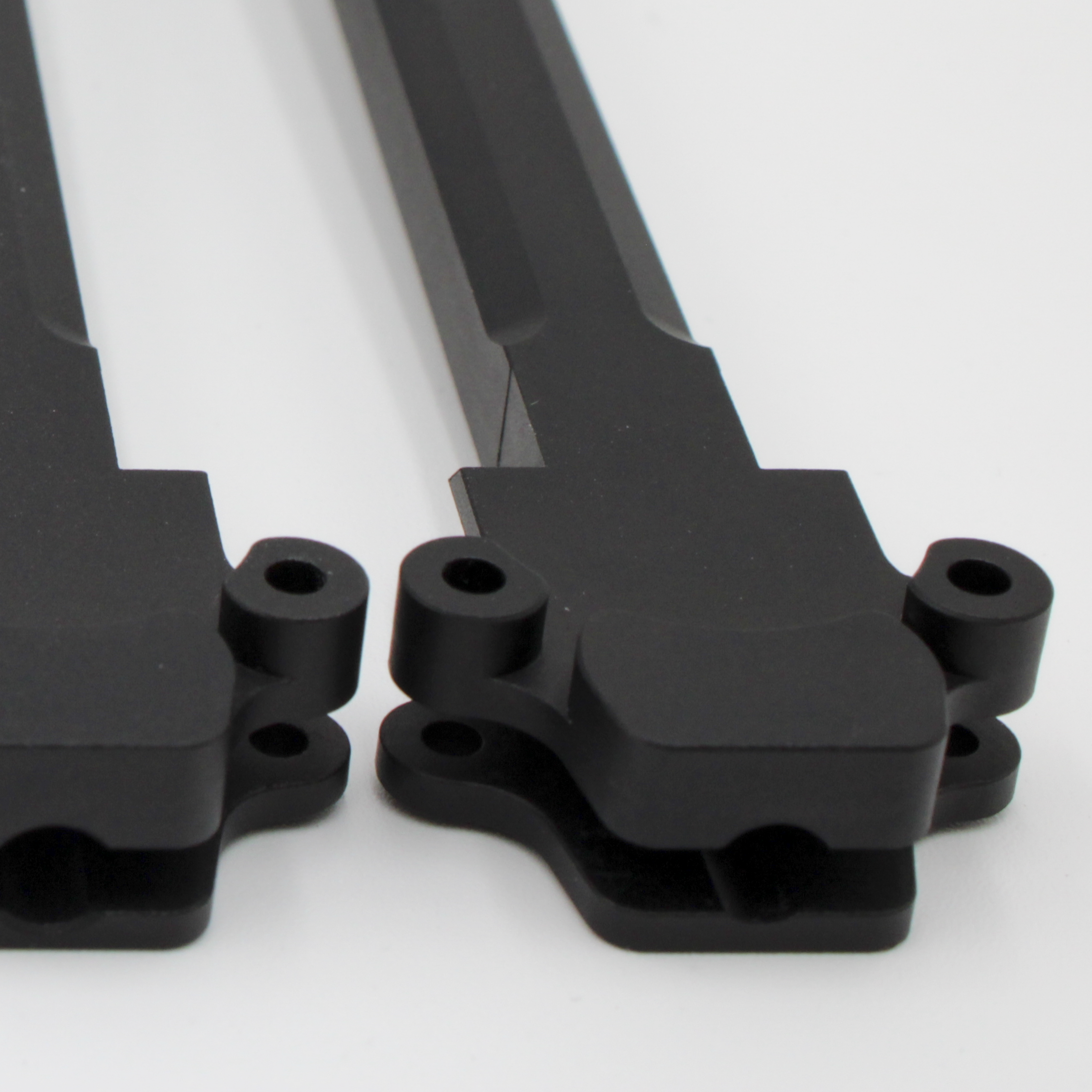

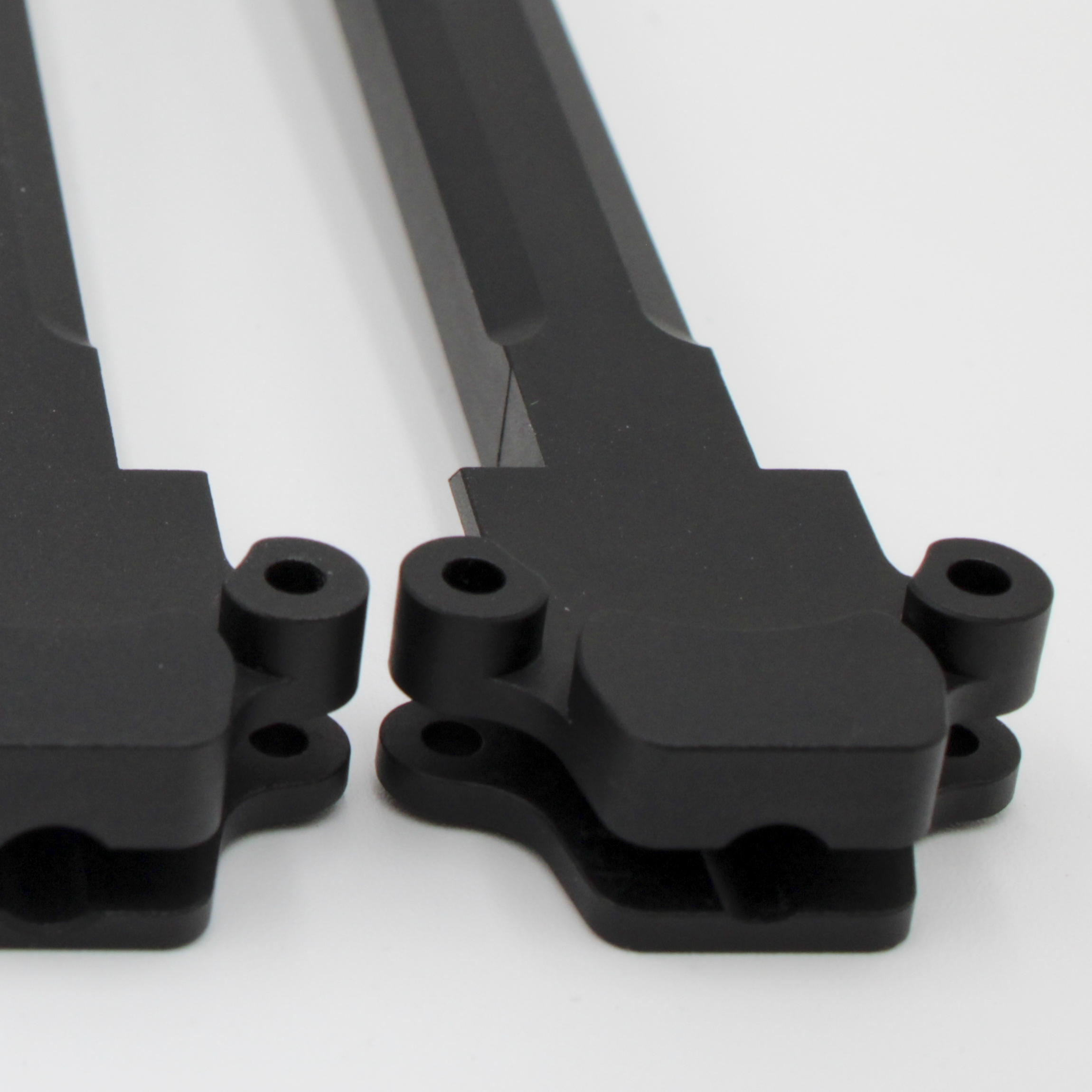

Etching removes a controlled layer of material from the metal surface, creating a clean, uniform texture ideal for bonding, coating, or adhesion. The process enhances mechanical grip and surface activation while ensuring consistency across components.

We accommodate Etch for the following:

- Available for aluminum

- Meets MIL specifications

Have Questions? Contact Us

OR CALL: (213) 986-2824

Your Preferred Anodizing Partner

George Industries applies precision-controlled etching using advanced chemical systems and real-time monitoring to ensure repeatable results. Our process expertise and compliance with aerospace standards make us a trusted partner for customers who require exacting surface preparation before coating or bonding.

Benefits of Type II Anodizing:

- Removes oxides, contaminants, and embedded residues

- Creates micro-roughness for superior coating adhesion

- Controlled depth ensures dimensional precision

- Improves paint, primer, and adhesive bonding performance

Industries Served:

- Aerospace and Defense

- Electronics and Semiconductor

- Automotive Manufacturing

- Precision Machining

Our Finish Sells the Product

Explore our range of finishing options

Anodizing

Painting

Mechanical Finishing

Color Options Available