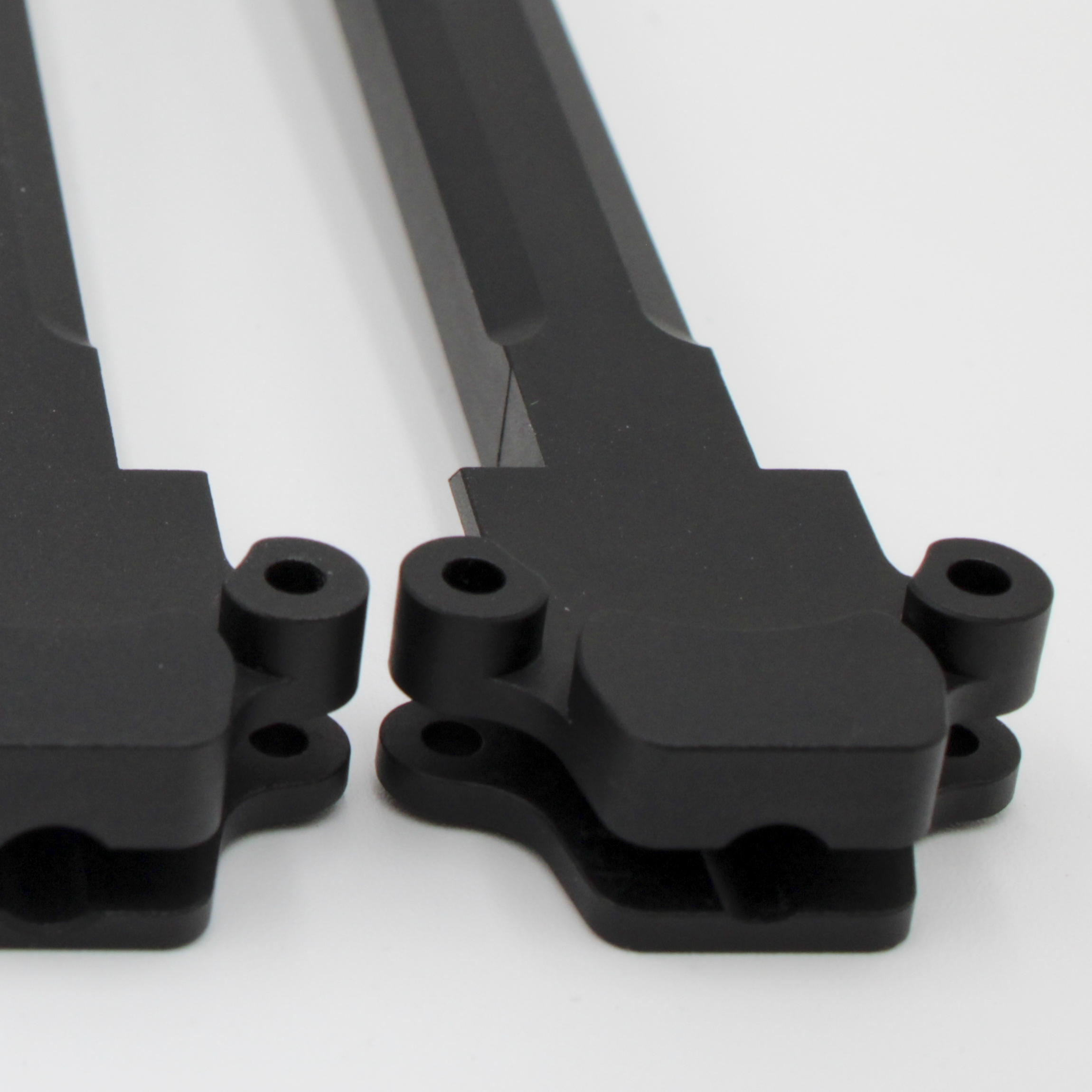

MIL-A-8625 TYPE II CLASS 1 CLEAR

SULFURIC ANODIZING

Type II Anodizing is an anodizing process that uses a sulfuric bath. These finishes offer good corrosion and wear resistance and are available in vibrant colors.

The Type II Anodize finishes we accommodate are:

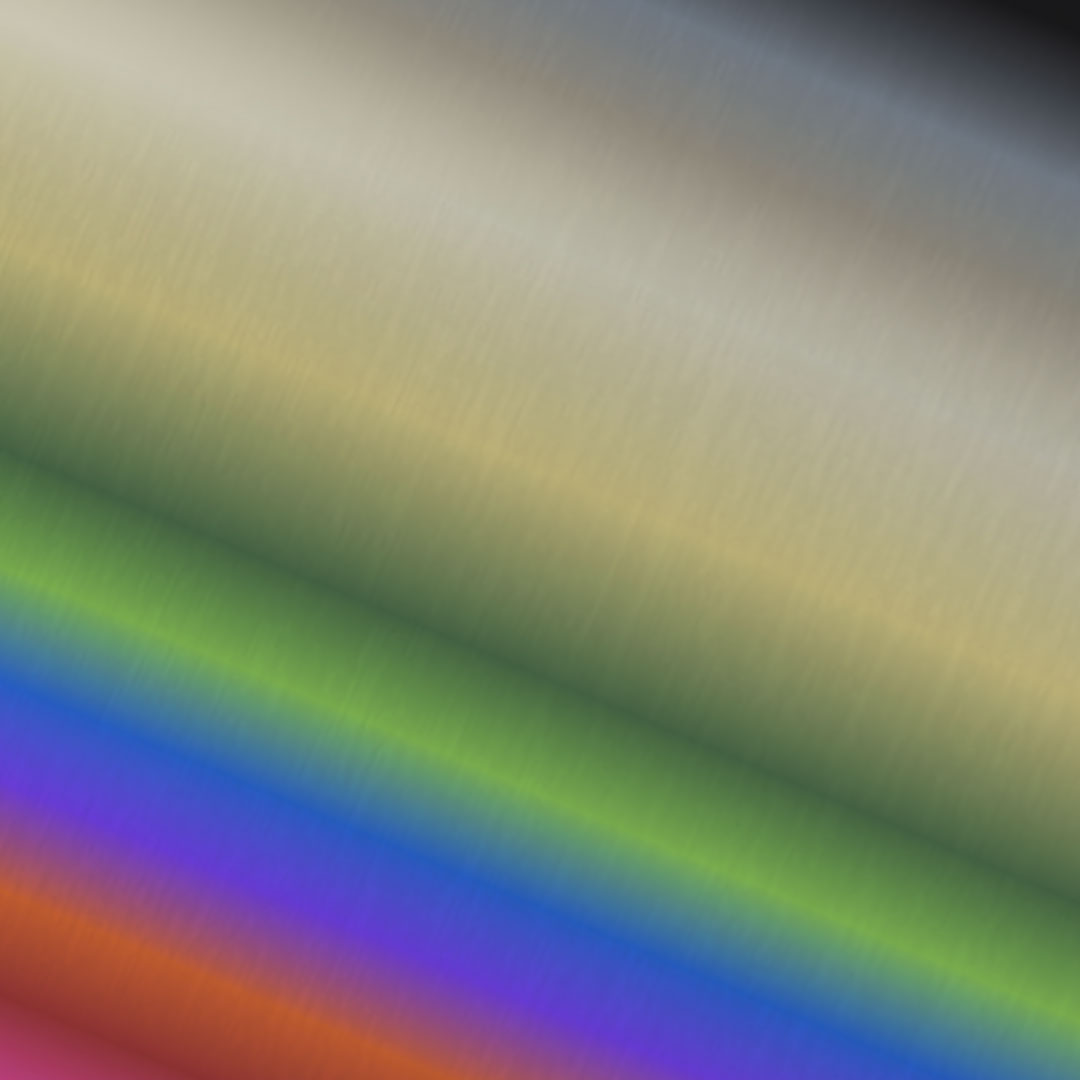

- Bright dip: a highly reflective and glossy finish, similar to a polished finish, that is ideal for use in cosmetic applications

- Clear: a decorative finish that displays the natural finish of the substrate

Pretreatments Available:

Polishing, Buffing, Time Saving, Brushing, Sand Blasting, Glass Bead Blasting, Masking, Bright Dip, Tumble Deburring, Acid Etching

Available Colors:

George Industries offers finishes in a wide range of in house colors. We can also can supply custom color matching and development at scale. For an up to date list of our colors offered, see our colors page

Tank Capacity and Racking Proficiency:

Rack and Bulk Processing

Have Questions? Contact Us

OR CALL: (213) 986-2824

Your Preferred Anodizing Partner

George Industries Type II anodizing process delivers consistent, high-quality oxide coatings on aluminum components, enhancing corrosion resistance and surface hardness. Using sulfuric acid electrolytes, we achieve controlled oxide layer thicknesses from 0.0001” to 0.001”, ideal for both cosmetic and functional applications.

Its advantages include lightweight durability, excellent wear resistance, enhanced adhesion for paints or glues, and compatibility with complex geometries.

Benefits of Type II Anodizing:

• Durability Enhancement

• Corrosion Resistance

• Thermal Insulation

• Aesthetic Versatility

Industries Served:

Aerospace, defense, automotive, electronics, medical devices, and consumer products. Its applications include housings, panels, structural brackets, precision-machined parts, and more.

Our Finish Sells the Product

Explore our range of finishing options

Anodizing

Painting

Mechanical Finishing

Color Options Available